Discover the Science of Chocolate Flavour

What makes chocolate so chocolaty?

Chocolate. We all love

it. Well most of us do. I am sure most of you have a specific brand

of chocolate that you like to eat. But have you ever wondered what exactly is responsible for creating that unique sensory experience?

Chocolate and cocoa products have a complex flavour. There are more than 600 volatile components in such products. Type and amount of these compounds and the way these compounds are made to react during the manufacturing process specify the flavour of the end products. Today, I’m writing about the 4 main factors that lead to the development of different chocolaty flavours.

1. The Birth Place and Genetic Origin of Cocoa- Cocoa is the main ingredient that influences the flavour in the final products. But not all cocoa beans are alike. Their genetics and geographical origin influence the final flavour in cocoa and cocoa products. Since the chemical composition of each variety of cocoa bean varies, each one of them will lead to the development of different, distinct flavours throughout the chocolate manufacturing process.

For instance, if you want floral spicy notes, you should source your beans from Ecuador. If you want aromatic and winy notes, you can try to get your beans from America or West India.

2. Other Ingredients- The main ingredients used to make chocolate are cocoa, cocoa butter, sugar, whey protein, milk powder and emulsifiers. The production process along with the amount, type and quality of ingredients used contribute to the development of flavour in a bar of chocolate.

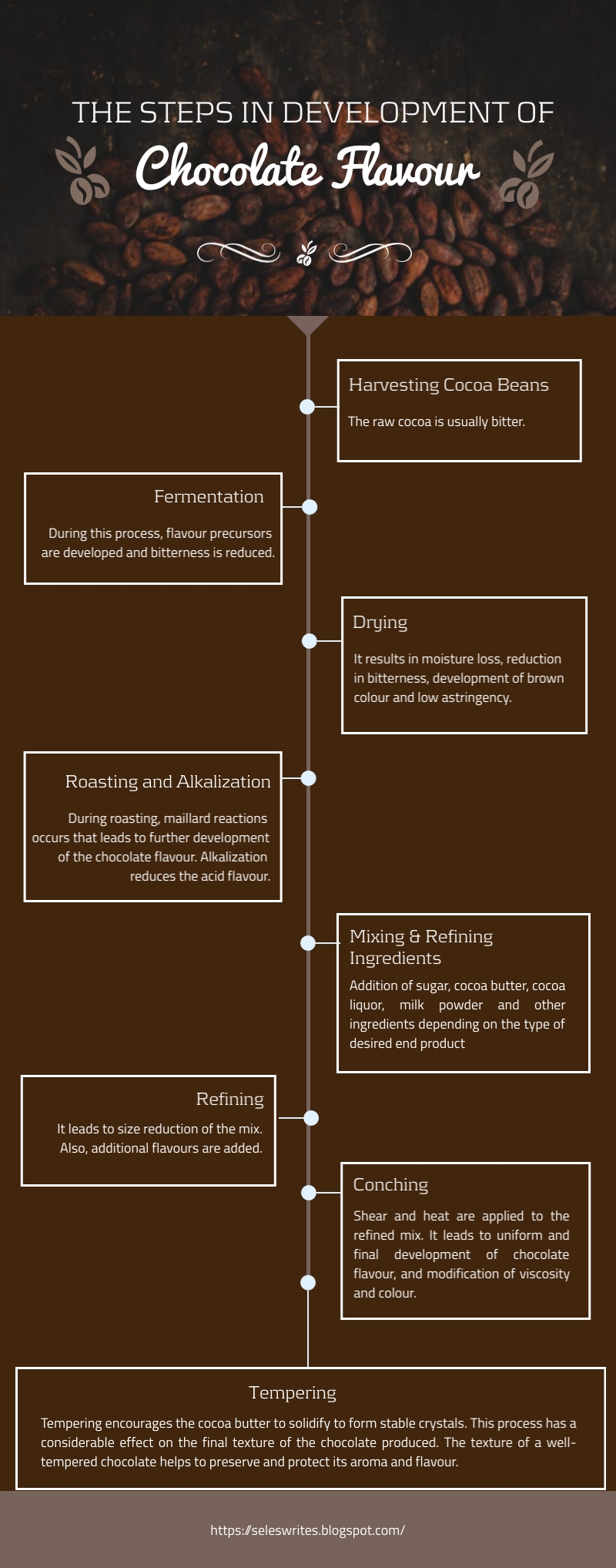

3. Post Harvest Treatments of Cocoa Beans- Fermentation and Drying Stages

The raw cocoa beans usually have a bitter note in their taste. That's why a lot of chocolate producers make their beans go through the fermentation process. The fermentation process involves placing the cocoa beans in a heap or a wooden box for 5-6 days and allowing microorganisms (yeasts, acetic acid bacteria and lactic acid bacteria) to do their magic on the raw beans. It helps to reduce the bitterness and leads to development of colour and flavour precursors.

Fermentation is usually followed by drying. Drying of cocoa beans leads to moisture loss and it continues till the moisture is below 8%. Within this stage, brown colour and new flavour compounds are developed. The method and temperature-time combination chosen for drying play a major role in flavour development. If the beans are dried fast, they may taste very acidic. Hence, the beans should be dried at lower temperatures for a longer time.

4.

Chocolate

Processing- Roasting, Refining, Conching and Tempering

Roasting

is a fundamental process in the development of the chocolate flavour. Before this process, beans may taste

rusty or sour. Roasting leads to the reduction in acidity and the formation of

desirable flavour fractions. Roasting time and temperature differ according to the equipment used and the desired flavour profile of the final product.

Refining

is a size reduction stage that can happen in two ways- blending all the

components and then grounding them or grounding all the components and then

blending them. The optimum particle size reduction influences the sensory experience

in the final product. For instance, with greater particle size of sugar, the

surface area of the sugar crystals (that comes in contact with your tongue) gets reduced and in turn, the sweetness of the sugar will be reduced.

Apart from this, when the sugar crystals become smaller, their surface becomes more

reactive and absorbs flavour compounds from cocoa and fat. Hence, smaller particles will also lead to uniform distribution of the flavour.

Conching determines the final flavour character. In this stage, the refined cocoa powder, along with the other ingredients is mixed inside a large container. This container is fitted with roller, paddles or a variety of other devices. Before conching, the chocolate flavour is just present on the particles of cocoa and cocoa butter. But during the process of conching, the cocoa flavour gets shifted to other ingredient particles, the outcome being a uniform chocolate flavour.

This

process can take a few hours and is performed at a wide range of temperatures.

The process conditions during conching vary depending on the type of flavour

you want your chocolate bar to have. The conching conditions such as time,

temperature and technique are the main factors that affect the flavour profile of

the chocolates. For milk chocolate, the mix will usually be treated at lower

temperatures (50°C–60°C). But if you want dark chocolate, the conching temperature

will be higher (65°C–80°C).

Tempering

is a process of heating and cooling done to stabilize the cocoa butter so that chocolate

doesn’t melt easily in your hands. The process of tempering helps to protect

and preserve the flavour of the final product.

These four are the main

factors that influence the chocolate flavour but they are not the only ones. In

addition, other processes involved in chocolate production also have a great

impact on the flavour characteristics.

Thank you :)

ReplyDelete